9 Composite Rings of 5m diameter for the ITER Core

Key figures

Weight of a ring

Operating temperature (-270 ° C)

Turns of composite material per ring

In 2016, F4E * entrusted CNIM Systèmes Industriels with the development of the manufacturing process and the production of three (6 + 3 spares) Pre-Compression Rings (PCRs), composite glass / epoxy rings to be used in the ITER reactor. Two years later, CNIM Systèmes Industriels was tasked to produce another six. The PCRs will withstand particular very high stresses (up to about 500 MPa MPa in hoop,) and a temperature of 4K (-270°C) when ITER will be in operation.

*F4E is the EU organization managing the European contribution to ITER https://www.fusionforenergy.europa.eu/

World first manufacturing process for large composite equipment

CNIM Systèmes Industriels teams have developed a highly innovative process to manufacture Pre-Compression Rings (PCR) in composite measuring 5m-in diameter to the nearest millimeter. Each ring is manufactured by winding and bonding 2mm-thick and 2,800m long pultruded* material, supplied by the Finnish company EXE, a 0.12 mm thick adhesive tape is inserted between each layer to fix the structure. A world first for such big composite parts.

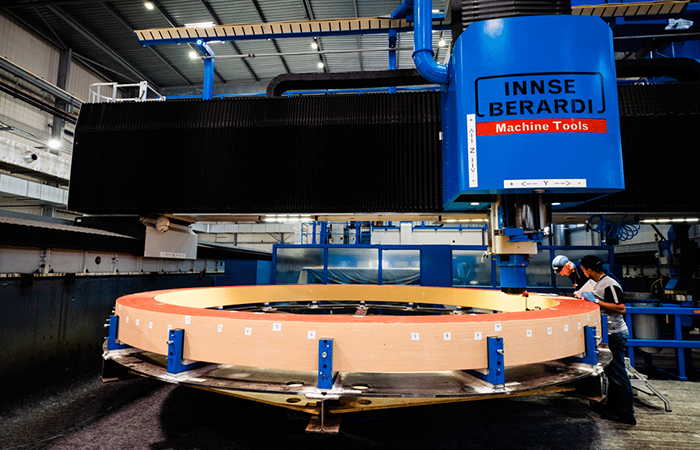

Dry machining of large-dimension composites

The rings are then machined to meet the tight required tolerances. With a strong experience in large-scale & high precision manufacturing, as was the case for ITER radial plates, CNIM Systèmes Industriels has developed dry machining of large-dimension composites.

An extraordinary test bench

The function of the rings is to reduce fatigue and deformation of toroidal field coils (superconducting magnets confining the 150 million °C plasma). During their 20 years of life, the Pre-Compression Rings will therefore be subjected to enormous physical stresses.

CNIM Systèmes Industriels, in consortium with Douce Hydro - expert in high-pressure hydraulics, has set up a specific test bench to qualify and validate the performance of the nine rings. The PCR Test Facility generates 36,000 tons of radial load thanks to 36 hydraulic cylinders synchronized to the nearest millimeter. The composite rings are subjected to efforts equivalent to the force it would take to lift four Eiffel Towers!

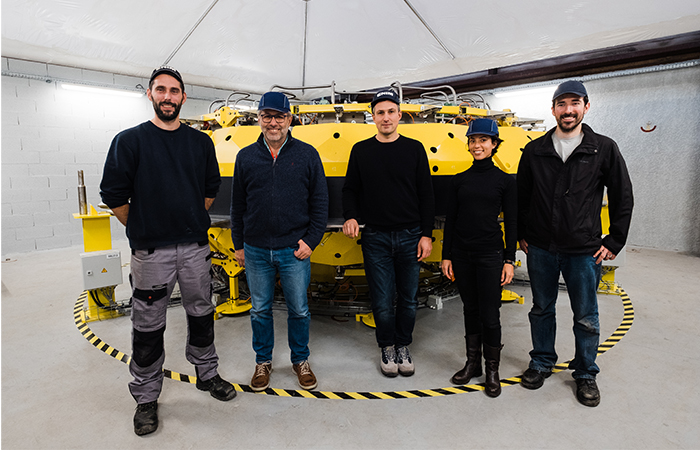

C. Legros (CSI), L. Semeraro (F4E), R. Besson (CSI), A. Hernandez Sanchez (F4E), V. Lecuyer (Douce Hydro) at the ITER Pre-Compression Rings facility, CNIM Systèmes Industriels, La Seyne-sur-Mer, France.