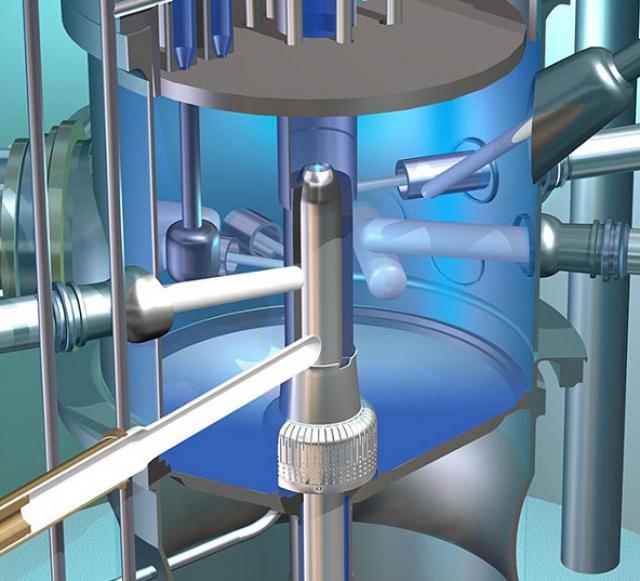

Ag3NET nuclear pressure equipment for the ILL’s High-Flux reactor

Key figures

equipments supplied since 2016

weight of each nuclear pressure equipment system

AG3NET weld thickness

In 2016, the Institut Laue-Lagenvin (ILL) in Grenoble - an international research centre at the cutting edge of nuclear science and technology - contracted CNIM Systèmes Industriels to manufacture beam tubes, which are key components of its High-Flux reactor.

These large, AG3NET nuclear pressure equipment systems enable neutrons to be extracted while keeping the reactor sealed from the reactor building hall.

Large components

The largest beam tubes measure 4.5 m in length and 1.7 m in diameter, and weigh approximately 2.5 tonnes.

As a specialist in small- and medium-scale production of large components for the most demanding industrial applications, CNIM Systèmes Industriels produces beam tubes to an 18-36 month schedule, depending on component complexity.

Close cooperation between ILL and CNIM Systèmes Industriels

- Production of large nuclear pressure equipment components

- Electron beam welding of Ag3NET aluminium alloy (with a Procedure Qualification Record - PCR) – one of the most difficult materials to weld

- Full-spectrum expertise in component quality & inspection procedures

ILL and CNIM Systèmes Industriels have built a long-term partnership in order to manage the replacement cycle for these high value-added components.

Document and regulatory follow up: meeting our partners’ demanding standards

Compiling the manufacturer’s file (for subsequent approval by an independent organisation appointed by the French nuclear safety authority) is a key step in the manufacturing process for these reactor components. CNIM Systèmes Industriels' teams are used to working with major European manufacturers, and maintain a document and regulatory watch that meets their customers’ requirements.

Ag3NET - ultra high-performance material

When exposed to neutron flux, Ag3NET exhibits a degree of neutron transparency, low activation properties and high mechanical strength, making it an ideal choice for use in the ILL beam tubes.

CNIM Systèmes Industriels introduced special processes for welding Ag3NET up to 30 mm thick in order to address ILL’s needs. Some welders received additional training for this project, making it a feature of CNIM Systèmes Industriels' human resources development plan.

Quality controls with a high level of requirement

All welds are subjected to visual, dye-penetrant* and then X-ray inspections, to ensure a very high standard of component quality and performance. In the metrology room, all interfaces also undergo a geometry inspection. Lastly, a cold helium test is performed at a pressure of 30 bars, to ensure that components are leak-tight.

*Dye-penetrant inspection: non-destructive test (NDT) used in aviation and other technologically advanced industries

A trust-based relationship that led to the ordering of other equipment

More recently, in 2019, ILL naturally chose CNIM Systèmes Industriels to construct a 4.5 m tall stainless steel and Zircaloy stack that will be installed inside the reactor.