Custom vehicle for transporting First World War chemical munitions

Specially-designed vehicles tackle the challenge of safely transporting chemical munitions on the road network without closing it to traffic.

Safe & secure transport

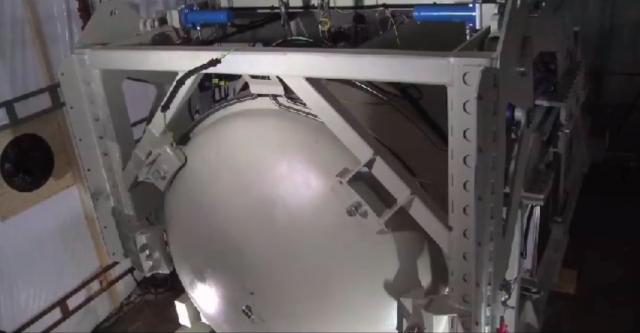

To enable chemical shells to be safely and securely moved from storage facilities to a destruction plant, CNIM Systèmes Industriels has designed and manufactured four Munitions Transport Vehicles (Véhicules de Transport des Munitions - VTM) with tamper-proof, leaktight armoured tanks for the French armed forces ministry.

Key figures

Vehicles delivered

Gross Train Weight (GTW)

Eq. TNT: tank burst strength

Mandatory destruction of munitions

Hundreds of millions of shells were fired during the First World War, an estimated one-tenth of which failed to explode. Between 10 and 20 tonnes of chemical munitions are unearthed each year. The Chemical Weapons Convention (CWC), which was signed in 1993 and came into force in 1997, requires them to be safely destroyed in accordance with environmental legislation.

Unlike conventional shells, which can be eliminated using proven industrial processes, the only way to dispose of chemical shells is to blow them up in a secure, open-air location. Such operations are more complex and require special techniques. To address this requirement, the SECOIA plant was built at the Mailly military base in northeast France.

Special-purpose vehicles approved for use on the road network

CNIM Systèmes Industriels has converted four Renault Trucks Kerax 8x4 vehicles. These trucks have a gross train weight (GTW) of 32 tonnes and comply with draconian safety standards.

Particular attention was paid to stability when designing the VTM. This aspect was qualified by performing overturning tests to demanding military vehicle acceptance criteria, based on specifications issued by the French military procurement agency (DGA).

CNIM Systèmes Industriels issued the corresponding certificate of conformity, in its capacity as a special-purpose vehicle manufacturer.

The vehicle acceptance procedure (RTI / CE 2007/46) and ADR certification (based on regulations governing the transportation of hazardous substances by road) were carried out by CNIM Systèmes Industriels and Renault Trucks.

A lightweight but fully armoured leak-tight tank

CNIM Systèmes Industriels partnered with Dynasafe to engineer the tank to deliver the necessary safety (in terms of leak-tightness, shielding and tamper-proofing) while remaining as lightweight as possible, in order to comply with the weight restrictions applicable to road transport.

During tests conducted in Sweden, the tank successfully withstood an explosion corresponding to >13 kg TNT-equivalent.

Safe shell handling

Alongside the three special-purpose vehicles, CNIM Systèmes Industriels has also supplied safe handling systems to enable shells to be loaded into and removed from the armoured tank.

Special-purpose vehicles

Learn more about CNIM Systèmes Industriels' comprehensive range of design and manufacturing services for special-purpose heavy vehicles for extreme-duty or highly specialised applications.