Successful installation of the ITER Upending Tool for components weighing up to 440 tonnes

Successful installation of the Upending Tool at the ITER site in Cadarache!

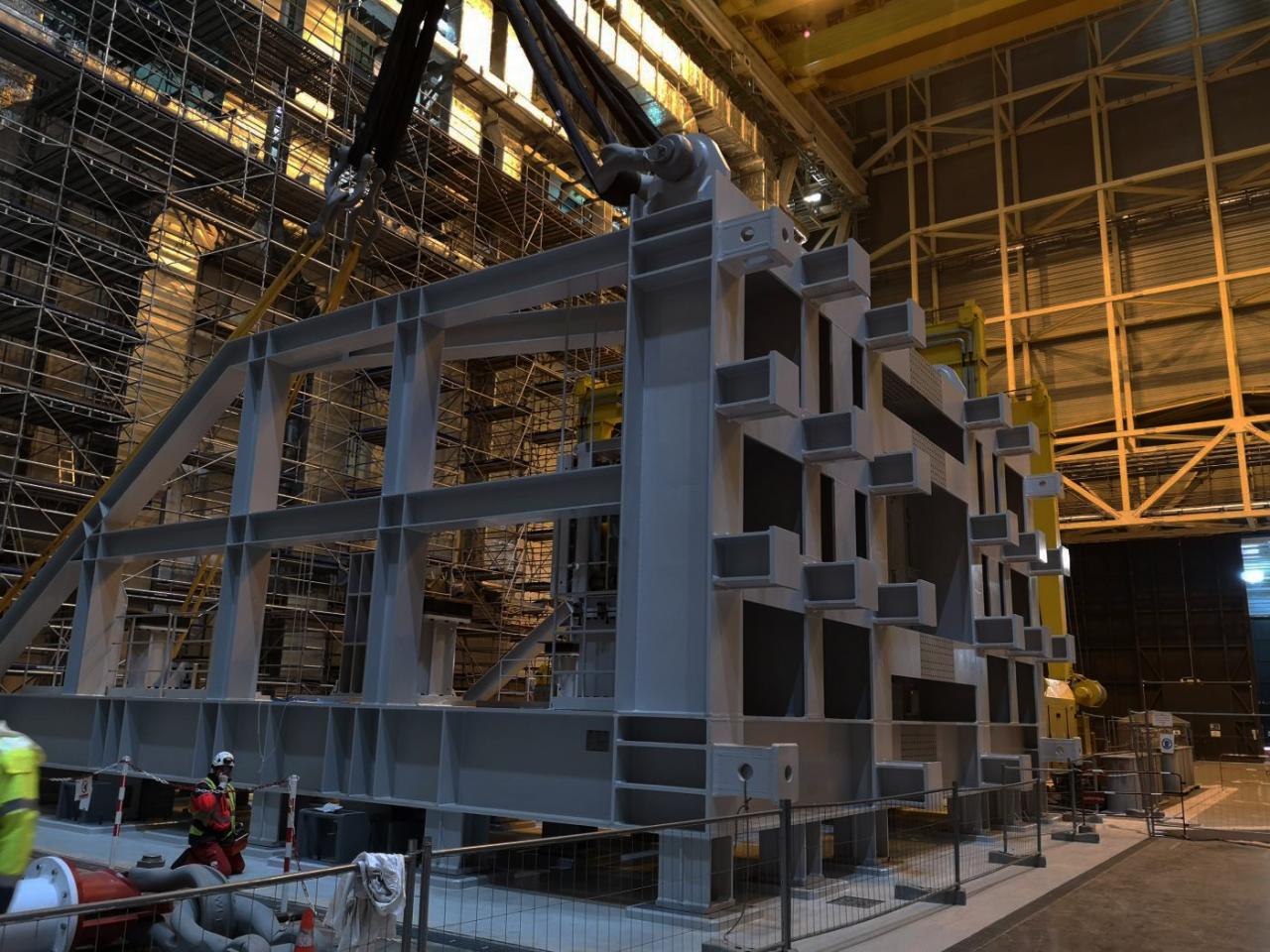

In February 2020, CNIM Systèmes Industriels successfully assembled the Upending Tool, a 200-tonne special-purpose installation designed to assemble and lift ITER components weighing several hundred tonnes, and then manoeuvre them into their final locations.

CNIM Systèmes Industriels has widely-acknowledged expertise in handling large, heavy loads

Following the successful installation of the two SSATs in the ITER assembly building, ITER Org awarded CNIM Systèmes Industriels the contract to install the Upending Tool in late 2018.

CNIM Systèmes Industriels was the obvious choice of partner for this contract, considering the company's expertise in the assembly of large components and our qualified team already present at the ITER site.

SSAT @ITER Org

The Upending system plays a key role in the ITER assembly process

The Upending tool, manufactured by a Korean partner (DOOSAN), performs an essential role in lifting and tilting components weighing up to 440 tonnes, enabling them to be assembled in the tokamak.

The various sections to be installed in the tokamak are delivered to the site in a horizontal position, but must be mounted vertically. The Upending Tool enables precise, delicate handling of the nine constituent sectors of the vacuum chamber, as well as the 18 toroidal field coils. Once upended, these components are lifted by a crane and carried to the SSATs, where they are permanently installed in the tokamak.

Millimetric preparation ensures successful assembly

In order to accommodate the 200-tonne Upending Tool, CNIM Systèmes Industriels' staff carried out the preparatory works with great precision and in a record-breaking 10 months. They:

/ Manufactured and installed 44 carbon steel floor anchor plates, each weighing 250 kg, as well as the upending tool's four stabilising legs,

/ Fastened more than 5,000 bolts,

/ Produced a special levelling concrete with custom formwork, poured in three casting operations over a nine-day period, to ensure excellent quality and obtain concrete able to withstand the planned multi-tonne floor loads,

/ Installed the anchor rods.

A great success

Our teams demonstrated their expertise in areas such as markings, high-precision metrology (with millimetric adjustments), drilling and paintwork.

Tests conducted with the ITER project teams to check the flatness of the mounting points were passed with flying colours!

A key role in the ITER reactor' assembly

The Upending Tool will be used from spring 2020 to straighten components of the tokamak, including the toroidal field and colloidal field coils.