Composites

With strong expertise in cutting-edge industrial fields, the CSI's teams offer to design with you your products in composite materials and shape them in our workshops.

Our multi-material expertise, both metallic and composite, will allow us to support you towards a product that combines performance, resistance and lifespan.

Thanks to composite materials, you can :

- Lighten your components currently made of metal,

- Guarantee a very high mechanical resistance of your components,

- Have parts that resist corrosion,

- Obtain long-life components in an irradiated environment,

- Ensure the resistance of your components subjected to powerfull electromagnetic forces.

Our expertise is mainly focused on structural parts. Whether lightened or reinforced, large, and/or for harsh environment, our structures meet the highest performance requirements.

Large composite structure with internal polyurethane parts.

Large composite rings subjected to very high loads (~500 MPa in annular tension) and to a temperature of 4K (-270°C).

Composite door meeting naval requirements (acoustics, lightness, operating reliability, etc.)

1 composite worshop 100% integrated

From design to full-scale parts qualification : everything happens on our industrial site in La Seyne-sur-mer with our teams. We are a a vertically integrated supplier, able to develop special processes and to industrialize them.

Our industrial tool is 100% adapted to large scale and the achievement of out-standing performance. Our composite workshop is part of this logic.

- XXL shaping : dry machining, winding of pultruded material, filament winding, infusion, pre-impregnation (autoclave)…

- Large dimension metrology

- Laboratory dedicaded to material choices and characterizations

- Heat treaments (XXL ovens, autoclave)

- Scale 1 test benches to validate the expected performances. Custom developed.

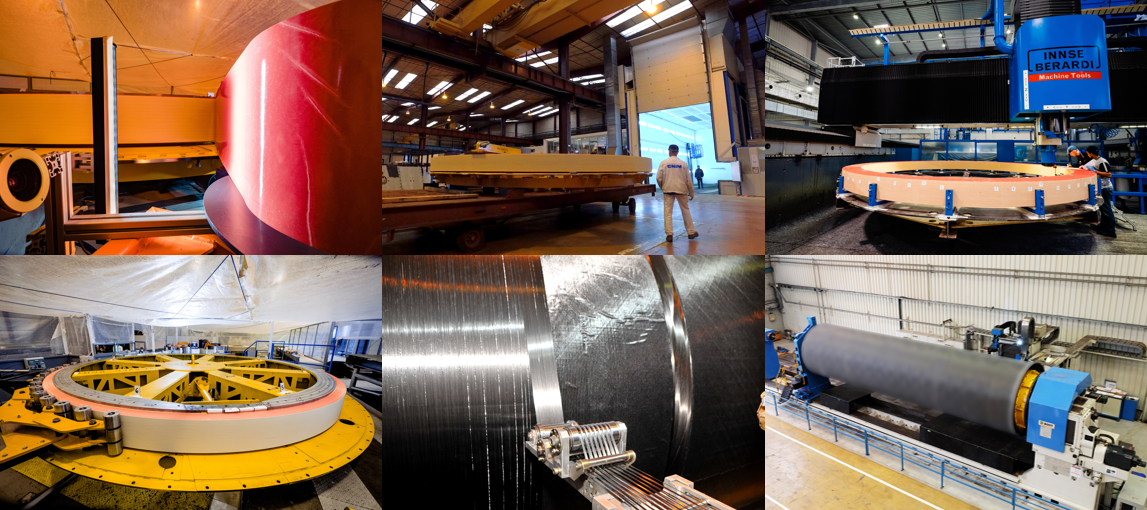

Shaping of composite parts in the CSI workshops (photos from left to right): winding of pultruded material, curing of composite parts in an XXL oven, dry machining, winding of pultruded material, filament winding, machining on a horizontal lathe

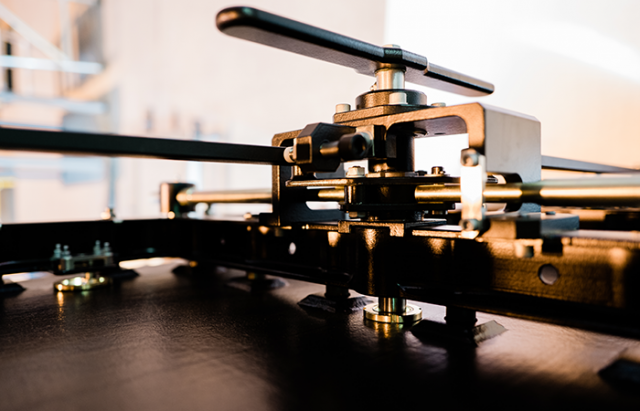

Our large autoclave (2.5 x 2.5 x 7 m) for heat treatment on composite parts.

Contact us

For more information, contact us!