Welded and composite components

Key figures

Welded thickness

Max length of machined parts

Employees in the design office

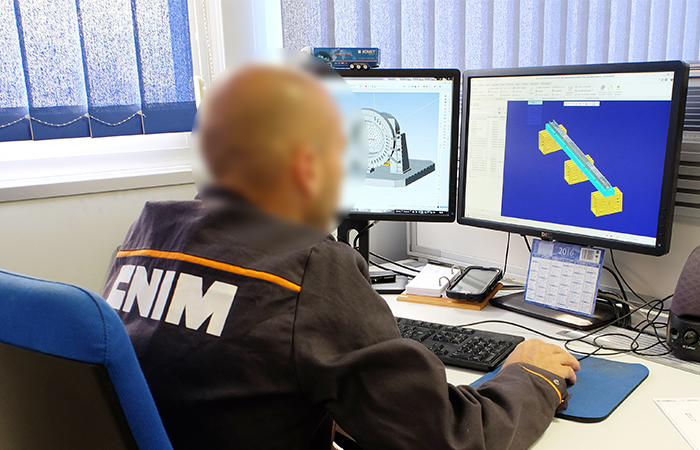

Co-engineering: optimizing manufacturing and reducing costs

CNIM Systèmes Industriels has long-lasting experience in design, industrialization and manufacturing in the demanding sectors of the Industry. For space applications, we are able to be your partner and co-design your components to optimize manufacturing, both in terms of cost reduction and improved production efficiency. Before the production runs, we qualify the prototypes developed together.

While guaranteeing the mechanical characteristics (static, dynamic, resistance) of the component, our teams seek to optimize the weight of the part when it is on board launchers for example.

Performant industrialization for efficient manufacturing

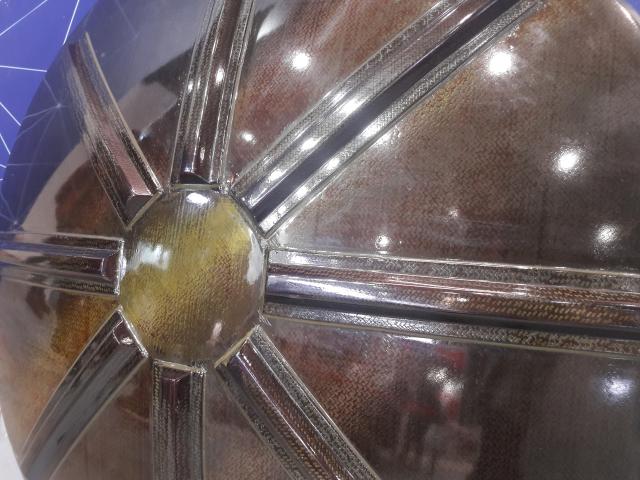

Materials expertise: mastery of composites

Fairing, tank, panels, radomes... what if the lightening of these components went through the implementation of high performance composite materials? CNIM Systèmes Industriels supports its customers in the development of composite solutions and the achievement of very demanding specifications (harsh environments, lifespan, resistance to radiation, sealing, etc.)

Qualification of manufacturing and welding processes

Our teams both work in a clean environment and master state-of-the-art materials such as aluminum, high-performance alloys with aluminum including Ag3Net, stainless steel or even titanium. At CNIM Systèmes Industriels, if required we qualify special manufacturing processes for your project, while complying with RCC-MX, EPSN codes, etc.

Each welding process is also QMOS/DMOS qualified. Electron beam welding allows us to weld up to 65 mm thick. For very large components, we have the ability to do local vacuum electron beam welding.

Electron beam welding under local vacuum

Extensive 3D tests and controls

Our large-size components meet the requirements required by players in the space industry and other cutting-edge sectors in terms of safety, technical performance (strength, geometry, stability, etc.) and operational reliability in a constrained environment.

CNIM Systèmes Industriels are highly qualified (COFFMET 3 in 3D inspection and COFREND 3 in welding inspection – the highest levels).

On site, they carry out non-destructive testing of welds, dimensional inspections (laser trackers or metrology machines in an air-conditioned room) and can, depending on the needs of the project, develop a full-scale test bench.

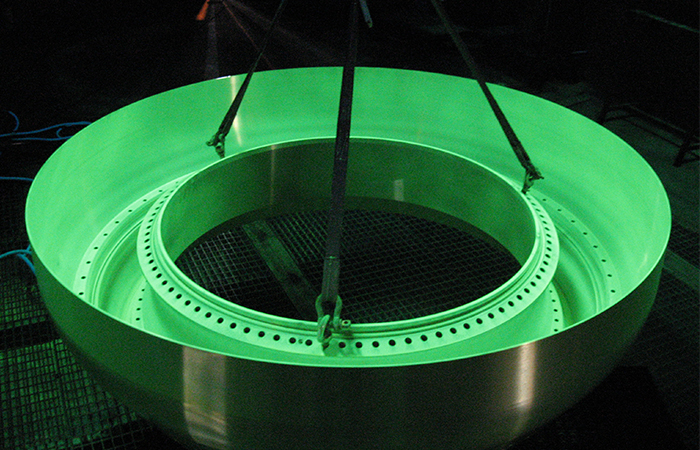

Fluorescent dye testing

Contact us

For more information, contact us!