26 May 2020

Nuclear industry and Big Science

ITER cryostat base is in place: CNIM Systèmes Industriels' handling system balances its 1,250 tons

26th, May, 2020. A major milestone was reached on the ITER project when the cryostat base was installed in its final location. This is the start of the tokamak assembly, a reactor capable of generating a 150-million-degrees plasma to create the long-awaited fusion reaction.

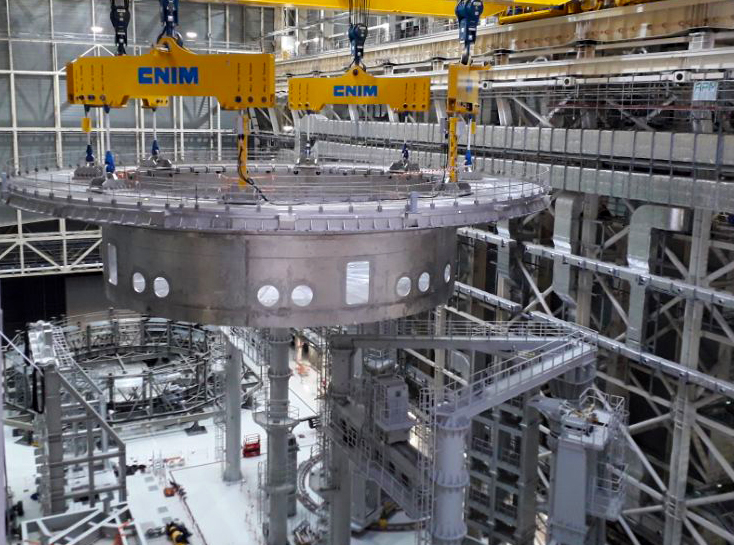

Photo: the cryostat base is routed for 150 m to the tokamak through the assembly building, flying over the SSAT at 30 m high.

The assembly of the ITER tokamak has started

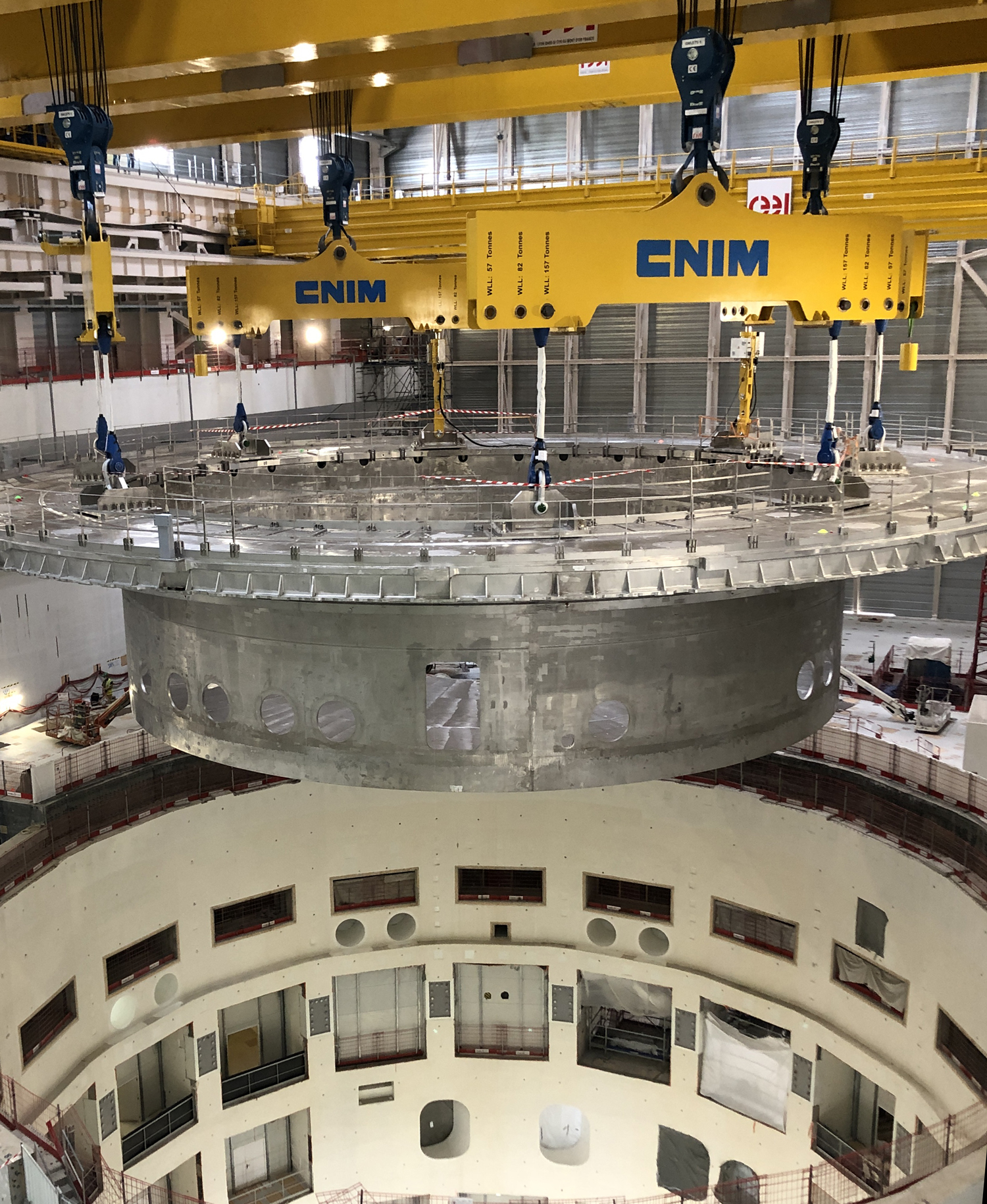

Handling of the cryostat base, the heaviest of all the ITER machine components with its 1250 tons and 30-meters diameter, was complex. From the entrance to the assembly building to its final position, the cryostat had to be lifted above the 2 SSATs* and then slowly lowered into the pit. Precise balance was the challenge of this operation. Indeed, it was necessary to guarantee the distribution of the enormous load on the four hooks of the bridge to avoid any risk of damage to the winches which could cause a dramatic fall.

* SSAT: Sector-Sub Assembly Tool. These two tools assemble the sub-sectors of the tokamak to the nearest millimeter. They measure 22 m high and have a lifting capacity of more than 800 tons. More details on SSAT's assembly, done on site by CNIM’ Systèmes Industriels' teams.

Watch the video of the handling of the cryostat base :

CNIM Systèmes Industriels' teams participated in this success with the preparation of the concrete crown hosting the cryostat base and with the design and manufacturing of the handling system of the base itself. This system composed of 4 lifting beams fitted with hydraulic cylinders was designed by engineers from CNIM Systèmes Industriels' design office in La Seyne-sur-Mer.

Photo : the cryostat base is ready to descend into the tokamak pitl for its final installation.

Heavy and complex handling: at the heart of CNIM's know-how

“CNIM Systèmes Industriels has recognized expertise in specific handling systems for over 30 years. We are used to dimensioning our systems for very heavy loads, complex kinematics, extremely precise positioning, all in an environment with high constraints as can be ITER.” explains Jean-Claude Cercassi, CNIM Systèmes Industriels's sales manager for the ITER project.

CNIM Systèmes Industriels was in fact called upon by ITER Organization to design and manufacture non-standard handling tools necessary for the assembly of the tokamak under the "Purpose Built Tool" contract won in 2016.

Photo: Guillaume R. and Cédric R., respectively project manager and technical manager on the "Purpose Built Tool Equipment" project. Thank you to them and their team for their commitment!