Manufacture of large size mechanical components

CNIM Systèmes Industriels mass produces large size, high-precision build-to-print parts.

From superconducting magnet components and parts for optomechanical systems to vacuum chambers, our teams fully master the processes of manufacturing and inspecting complex parts.

Process industrialisation

CNIM Systèmes Industriels works closely alongside its customers to industrialise the parts to be manufactured.

This capacity allows our teams to ensure the manufacturability of highly sophisticated parts.

Our aim : ensuring the feasibility of our customers’ projects while adhering to lead time, cost and quality criteria.

Multi-material expertise

The multi-material expertise of our teams coupled with our cutting-edge industrial facilities allows us to machine and weld materials with exceptional properties such as austenitic stainless steels, titanium and aluminium, thus guaranteeing the magnetic permeability essential to the sector.

We also machine composite materials.

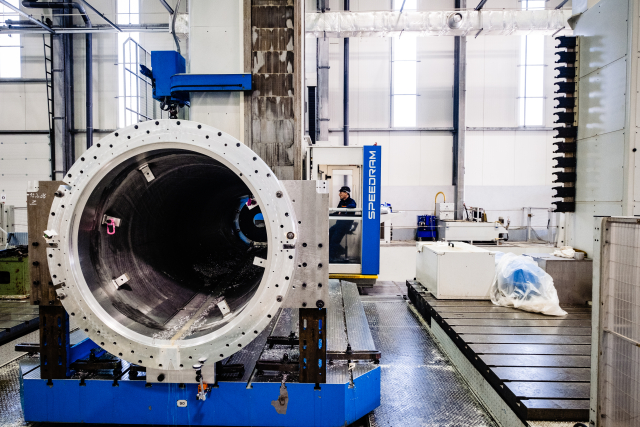

Machinery tailored to sector requirements

CNIM Systèmes Industriels boasts cutting-edge industrial facilities.

Harnessing our expertise in electron beam welding in a 230 m3 chamber, we manage the distortion of materials while guaranteeing the mechanical properties of parts.

Quality control

We are equipped with 3D inspection machines including the MMZ-G, one of the most efficient in Europe. CNIM Systèmes Industriels’ personnel are highly qualified, up to COFREND* level 3.

Specific tests (including hydraulic testing and helium leak testing up to 10-10 mbar.l/s) for each individual project can be performed in our workshops.

Our non-destructive testing guarantees the reliability of vacuum chambers manufactured in our workshops. We also provide magnetic permeability measurements.

Our achievements

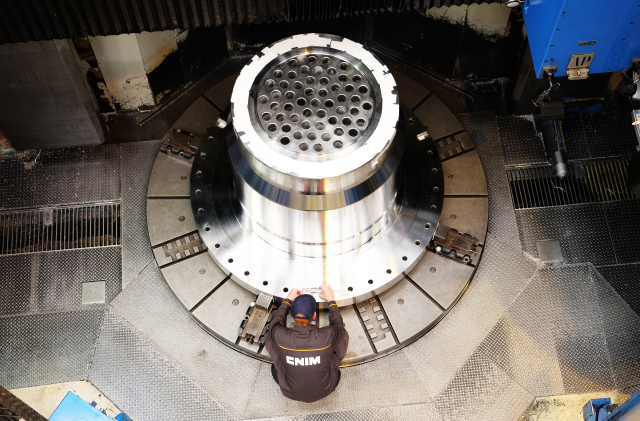

Radial plates for superconducting magnets

CNIM Systèmes Industriels and its Italian partner SIMIC manufactured 70 radial plates for the ITER research reactor.

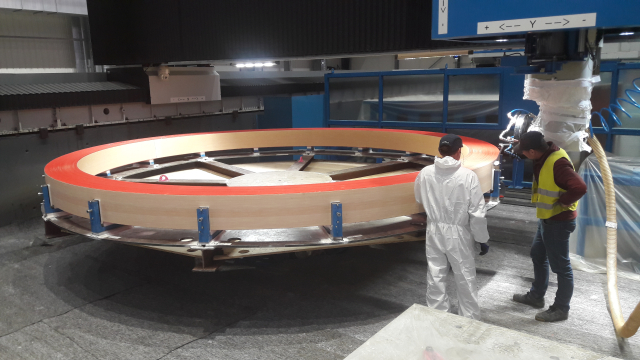

Very large size composite rings

The CNIM Systèmes Industriels teams have developed a highly innovative process for manufacturing 5-metre-diameter composite Pre-Compression Rings (PCR) to the nearest millimetre. The PCRs withstand particular very high stresses.

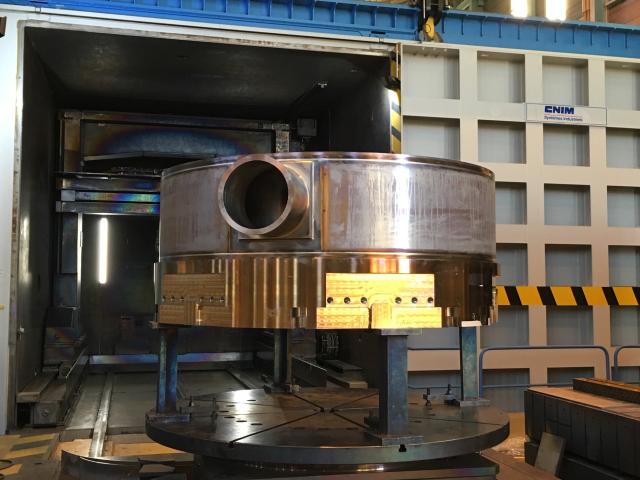

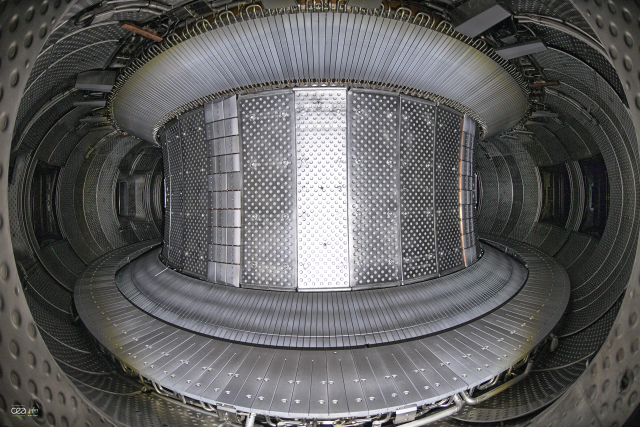

Divertor West

CNIM Systèmes Industriels provided the CEA (French Alternative Energies and Atomic Energy Commission) with the divertor casing for WEST’s tokamak in Cadarache.

A key component, the divertor is directly in contact with the thermal and particulate flows stemming from the plasma during experiments.

Contact us

For more information, contact us!