Significant industrialisation capabilities

CNIM Systèmes Industriels is a valued partner of major industrial groups and works hand in hand with its customers to industrialise parts for the most demanding sectors. In fact, our teams’ extremely powerful industrialisation capabilities specifically guarantee the manufacturability of products.

We aim to ensure the feasibility of our customers’ projects, while adhering to, or even optimising, lead time, cost and quality criteria.

Expertise with multiple materials

CNIM Systèmes Industriels’ multi-material expertise allows us to devise the best solutions for complying with the most exacting specifications. Our teams are experts in machining and welding heavy-gauge advanced materials, including:

Carbon and stainless steel: all grades

Aluminium alloys: 5083 - 6061 - 6082 - 7010 - 7020 - AS7G06 - AG3NET

Cutting edge, project-specific materials: Titanium, duplex / superduplex alloys, Inconel, copper alloys.

A suitable array of machines for nuclear equipment

CNIM Systèmes Industriels has state-of-the-art industrial facilities enabling it to satisfy the most exacting specifications.

Large format complex machining equipment, electron beam welding, a stress relief furnace and metrology using an XXL three-dimensional inspection machine allow us to achieve unparalleled manufacturing tolerances.

Tests

Specific tests (including hydraulic testing and helium leak testing up to 10-10mbar.l/s) for each individual project can be performed in our workshops.

CNIM Systèmes Industriels’ personnel are highly qualified, up to COFREND* level 3. Our non-destructive testing guarantees the reliability of vacuum vessels produced in our workshops.

*COFREND: French certification body for the interpretation of non-destructive test results

Our large format pressure equipment satisfies the nuclear sector's most rigorous standards (RCCM, CODAP, ASME, ESPN, etc.).

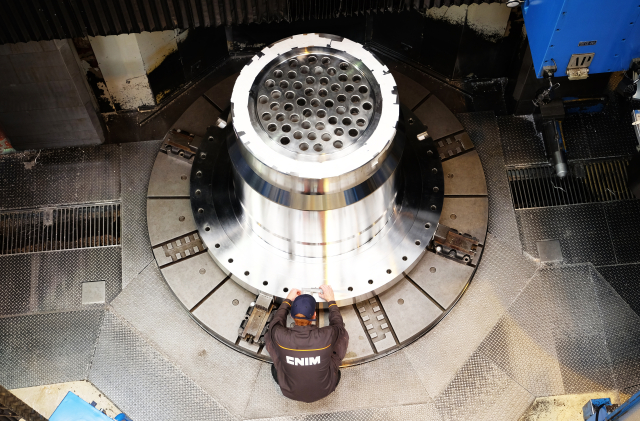

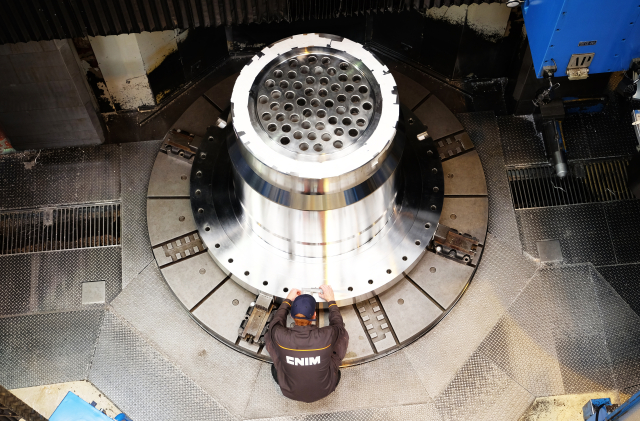

Reactor block

Our customers benefit from the skills we have acquired over many years. The core of the Jules Horowitz reactor built in CNIM Systèmes Industriels’ workshops and installed at Cadarache provides an example of the operational excellence of our welding and machining. This equipment is classified as ESPN N2 (Level 2 NPE).

Beam tubes

Since 2016, the Institut Laue-Lagenvin (ILL) has entrusted CNIM Systèmes Industriels with the manufacture of key equipment for its high-flux reactor: the beam tubes.

This large format AG3NET nuclear pressure equipment (NPE) enables neutrons to be extracted while ensuring the reactor core is sealed off from the reactor building hall.

Critical packages containers

Ensuring the integrity of packages and protecting users from ionising radiation are the challenges addressed by our critical containers.

We design, produce and qualify containers for transporting, storing and handling radioactive / high-added value / critical / heavy packages.

Our ability to work with very high-level specifications allows us to position ourselves as a key partner in the nuclear, defence and deterrence sectors.

Contact us

For more information, contact us !