Advanced nuclear components manufacture

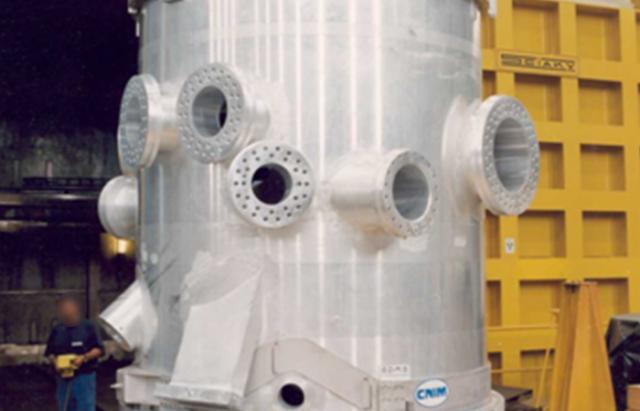

CNIM Systèmes Industriels designs and manufactures large and complex nuclear equipment under pressure, critical containers, large vacuum vessels and mechanically welded parts that comply with national and international standards in the nuclear sector.

Our teams master noble materials (specialty alloys, AG3NET, Aluminum, Stainless steel, Duplex, Inconel, etc.) and organic materials (polyurethane and composite). We offer you the best solution adapted to your needs.

Video - CNIM Systèmes Industriels'offer for the Nuclear sector

Nuclear equipment under pressure

Our pressure equipment is large and meets the most demanding standards in the nuclear sector (RCCM, CODAP, ASME, ESPN...).

Our clients benefit from our skills consolidated by recurrence. Our industrial tool able us to manufacture large dimension parts and to meet the quality requirements of the cutting edge sectors of the industry.

The core of the Jules Horowitz reactor (RJH) built in CNIM Systèmes Industriels' workshops and fitted at Cadarache offers an example of the operational excellence of our machining. The very high precision of our manufacturing allows the repeatability of the installation. The equipment is ESPN classified (French Nuclear Equipment Under Pressure).

Holder of a patent, CNIM Systèmes Industriels has contributed its unique expertise in electron beam welding while assembling very large size aluminium parts to comply with the RCCM code.

Vacuum vessels

Our capabilities in large and complex machining, electron beam welding and advanced controls, combined with our know-how in the design and manufacture of pressure equipment, allow us to offer our customers large vacuum chambers. for cutting-edge applications such as nuclear research or big science.

Specific tests (including hydraulic tests and leakage tests with helium at 10-10mbar.l / s) and specific to each project are carried out on our vacuum chambers. CNIM Systèmes Industriels' staff are highly qualified, up to level 3 of COFREND *. Our non-destructive testing guarantees the reliability of the vacuum chambers manufactured in our workshops.

* COFREND: French certification body for the interpretation of the results of non-destructive testing

Critical containers

Ensuring the integrity of the sensitive package is the challenge to which our critical containers respond.

We design, manufacture and qualify containers for the transport, storage and handling of radioactive, high value added, sensitive, heavy packages. At the request of our customers, our containers for critical use most of the time go with secure handling systems, systems for which we benefit from a long experience feedback.

Our ability to take into account very high-level specifications allows us to position ourselves as a key partner in the sectors of Nuclear, Defense and Deterrence.

We are committed to long-term relationships.

Large size, high precision mechanical structures

The cutting-edge industrial tool and the unique know-how of our teams allow the manufacturing of large parts with a very high level of precision, complying with the most stringent nuclear requirements.

In order to achieve the highest level of performance and precision, we have two ISO 6 to 8 clean rooms for the mass production of our products.

CNIM Systèmes Industriels has made 35 radial plates (ITER tokamak structure) measuring 14 m x 9m, with a flatness tolerance of a tenth of a millimeter.

Very high performance sealing systems

Thanks to their expertise in military and civilian nuclear research programs, but also in cutting-edge sectors such as Deterrence, our teams have extensive experience in composite and polyurethane materials.

In order to verify their efficiency in situ and to guarantee their performance, CNIM Systèmes Industriels ensures the qualification of materials in a nuclear environment and the scale 1 test of designed and manufactured parts.

For example, CNIM Systèmes Industriels designed the very high performance polyurethane membrane for the containment of the damaged reactor at the Chernobyl power plant. The 3 km of membrane were mass-produced in our workshops. This exceptional equipment is also exceptional by its long-term resistance to radioactive flows or class 3 tornadoes.

Contact us

For more information, contact us!