Large and high-accuracy manufacturing

CNIM Systèmes Industriels offers a wide range of large machining equipment, welding expertise (including electron beam welding), composite & polyurethane material manufacturing and assembly in large clean room.

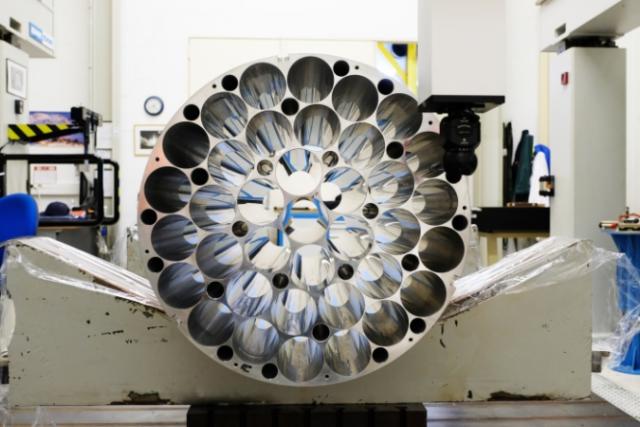

Radial Plates for ITER

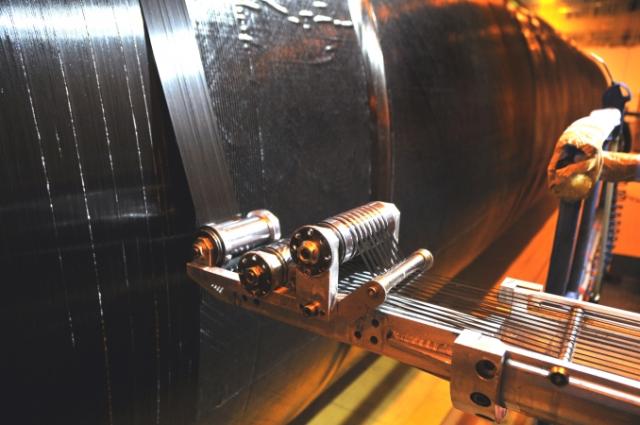

Electron beam welding, under local vacuum

3,000 sqm dedicated workshop

Large milling center: 9 x 36 m

400 t superconducting magnets

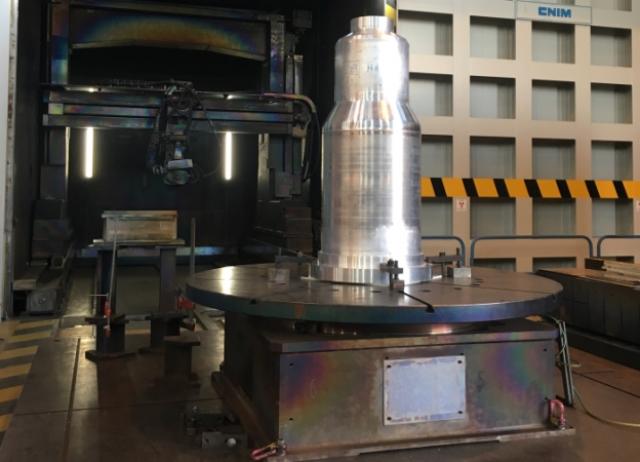

On-site manufacturing of 4 Four out of 6 Poloidal Field Coils for ITER (F4E)

Set-up manufacturing activity

Training & qualification of operators and processes

Niobium-Titanium superconducting cable

High stability mechanical frame

Supporting optical components and mounted on high precision actuators

ISO6 Clean room assembly

Photos credits: Laser Megajoule © CNIM Systèmes Industriels

Nuclear vessel

Inox and aluminum welding

Oil free metal machining, RCC-MX

Complex shapes

5-axis large boring machine

Photo credits: CNIM Systèmes Industriels

Electron beam welding

Manufacturing according RCC-MX codes

Electron beam welding of Ag3NET

230 welding m3 facility

Photo credits: Beam tubes © CNIM Systèmes Industriels / ILL

Glass fiber filament winding

Dedicated composite workshop

Photo credits: CNIM Systèmes Industriels

More information

Our offer for complex systems in harsh environment

Contact us

For more information, contact us!